Dear Sir

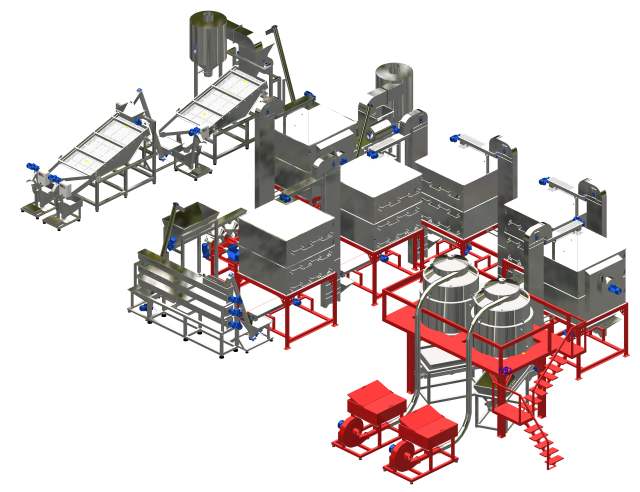

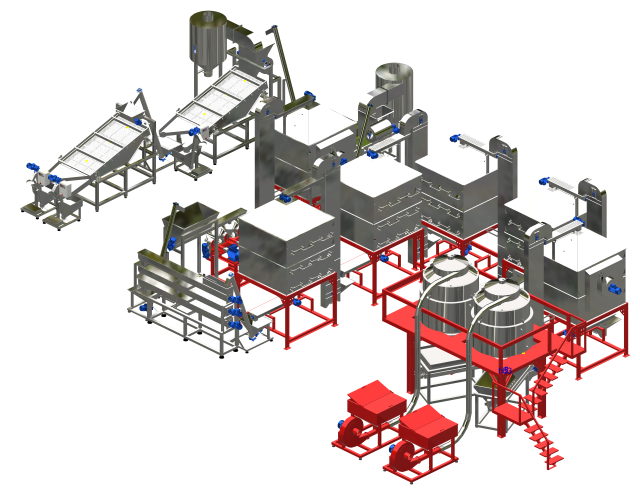

We are very pleased to present our new concept of the burghul production plant Model BP-100.

It operate continuously.

“BP-100” It is an advanced technology to produce Traditional Lebanese Burghul.

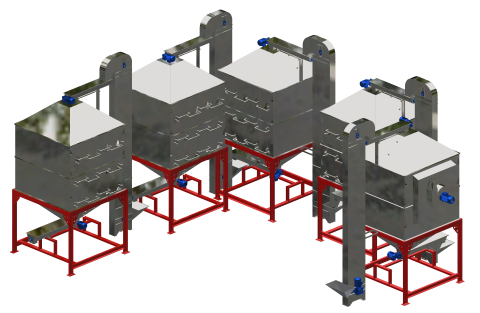

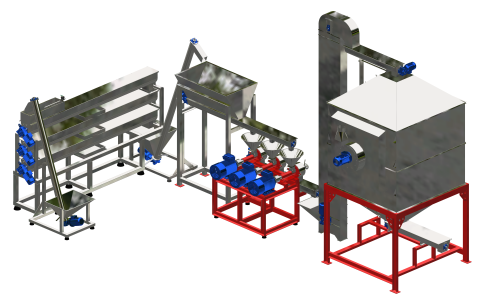

It is delicately cooked, dried and grinded. The dried boiled wheat is humidified and grinded by means

of disc grinder. With this method the outer film of the wheat grain is taken off during disc grinding.

We avoid losing any bran of the wheat grain and the burghul has already smooth and round shape.

It preserves all the vitamins and natural characteristic of wheat and gives a brand-new kind of Traditional

Lebanese Burghul.

It is light digestive, easy to cook in 15 to 20 minutes, absorbs less oil during cooking and marked by

its pure color, luscious smell and delicious taste.

AMBAR has designed and manufactured this system among many other innovations that contribute to

the continuously developing of food industries.

AMBAR takes the lead in the field of manufacturing, thanks to its two mottoes: loyalty & quality.

Over the decades, we have gained the trust of our customers.